CO₂ liquefaction

- Home

- CO₂ liquefaction

CO₂ purification and liquefaction

CO₂ liquefaction is the process of converting gaseous carbon dioxide into its liquid form, a process that transforms it from an emission to a versatile and transportable resource.

This step in fact allows the storage, transport and efficient use of CO₂ in various applications.

Furthermore, CO₂ purification and liquefaction plays a crucial role in carbon capture and storage initiatives, avoiding its release into the atmosphere in order to mitigate climate change. One more step towards decarbonisation.

Liquid CO₂ suitable for food and industrial use

The CO₂ liquefaction system designed by AB - DISCO₂VERY - allows purifying and liquefying the mixture composed mainly of carbon dioxide coming from the BIOCH4NGE® biomethane/RNG production system, in order to obtain liquid CO₂ suitable for food and industrial use.

The CO₂ produced by the plant complies with European legislation (Regulation (EU) no. 231/2012 – Additive E290) and with the international standard ISBT (International Society of Beverage Technologists) for the use of carbon dioxide in beverages.

The integrated cryogenic process

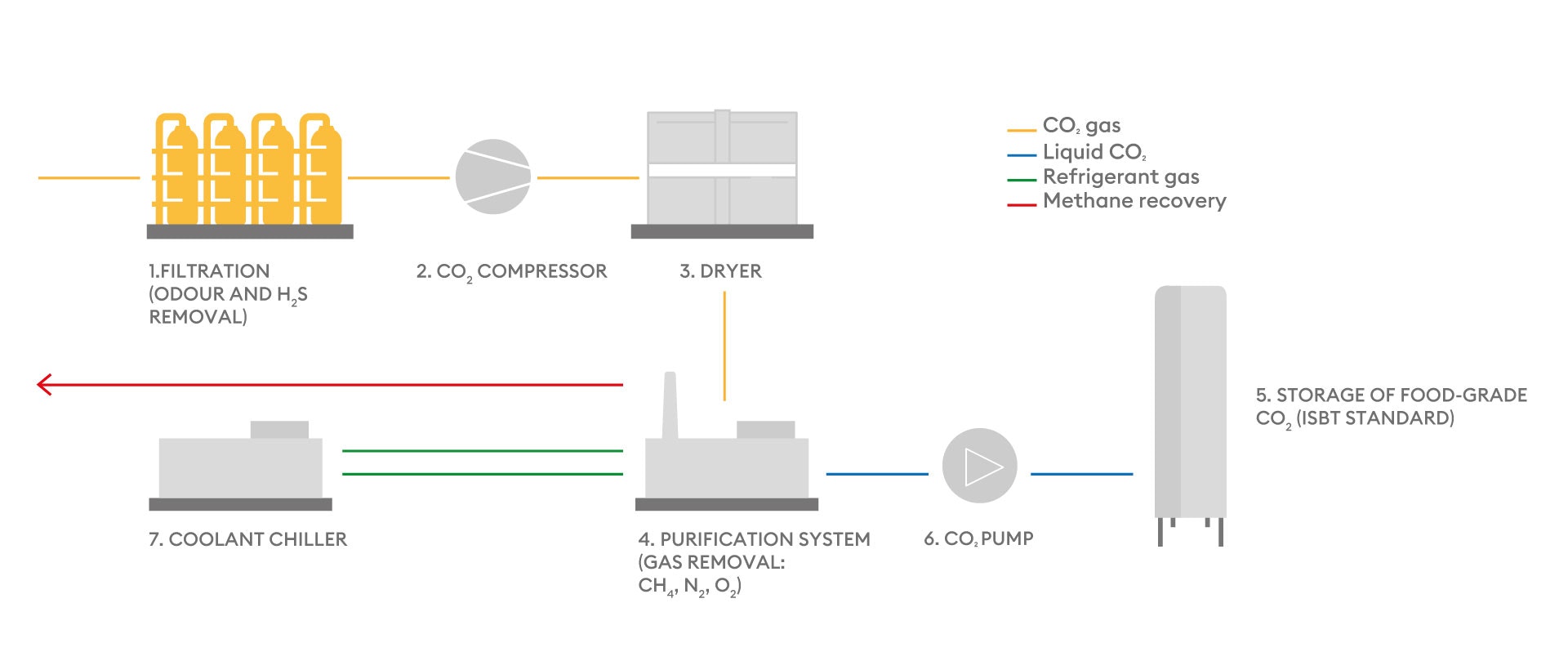

The plant is based on an integrated cryogenic process divided into 5 phases:

Treatment: during the first part of the process the purification system eliminates contaminants and odours through a system of activated carbon filters.

Compression: the gas is compressed to a pressure between 15 and 20 bar according to the customer's needs.

Drying: moisture is reduced through condensation and absorption on molecular sieves.

Cryogenic distillation: the extraneous gases (CH₄, N₂, O₂) present in the incoming mixture are separated from carbon dioxide by means of cryogenic distillation technology, which enables obtaining CO₂ with a content greater than 99.9% at the exit of the system, as required by the ISBT.

Storage: The bio-CO₂ is conveyed into a storage tank where it will be kept at the desired pressure and temperature conditions.