DISCO₂VERY

- Home

- DISCO₂VERY

AB's CO₂ liquefaction technology

AB's CO₂ liquefaction technology allows recovering carbon dioxide from the biogas upgrading process and converting it into liquid bioCO₂, suitable for the food industry. A further addition to our wide range of technological solutions, to enhance the emission deriving from the biomethane/RNG production process, transforming it into a precious resource.

Our CO₂ - DISCO₂VERY - liquefaction plants comply with rigorous safety and environmental standards and use state-of-the-art technologies to optimise the energy efficiency, reliability and purity of the liquid CO₂ produced. Designed as a containerised, plug-and-play solution, they ensure rapid installation and commissioning on site.

Uses of liquefied CO₂

AB's CO₂ liquefaction technology allows recovering carbon dioxide from the biogas upgrading process and converting it into liquid bioCO₂, suitable for the food industry. A further addition to our wide range of technological solutions, to enhance the emission deriving from the biomethane/RNG production process, transforming it into a precious resource.

Our CO₂ - DISCO2VERY - liquefaction plants comply with rigorous safety and environmental standards and use state-of-the-art technologies to optimise the energy efficiency, reliability and purity of the liquid CO₂ produced. Designed as a containerised, plug-and-play solution, they ensure rapid installation and commissioning on site.

Uses of liquefied CO₂

The CO₂ produced from biogas purification can be liquefied for transportation to where it is used: CO₂ injection in agricultural greenhouses, dry ice production, food processing industries, chemical industries, cooling liquid production.

Adding a CO₂ liquefaction plant to the biogas-to-biomethane upgrading system results in improved sustainability, revenue and CI-score.

The CI-score measures the amount of carbon dioxide (CO₂) emissions produced per unit of energy or fuel consumed. This is a fundamental measurement system used to assess the environmental impact of various energy sources. A lower CI-score indicates fewer CO₂ emissions associated with the energy produced, meaning a cleaner and more sustainable energy source.

The CO₂ produced by the plant complies with European legislation (Regulation (EU) no. 231/2012 – Additive E290) and the international standard (International Society of Beverage Technologists) for the use of carbon dioxide in beverages.

Discover how DISCO₂VERY works

The integrated cryogenic process

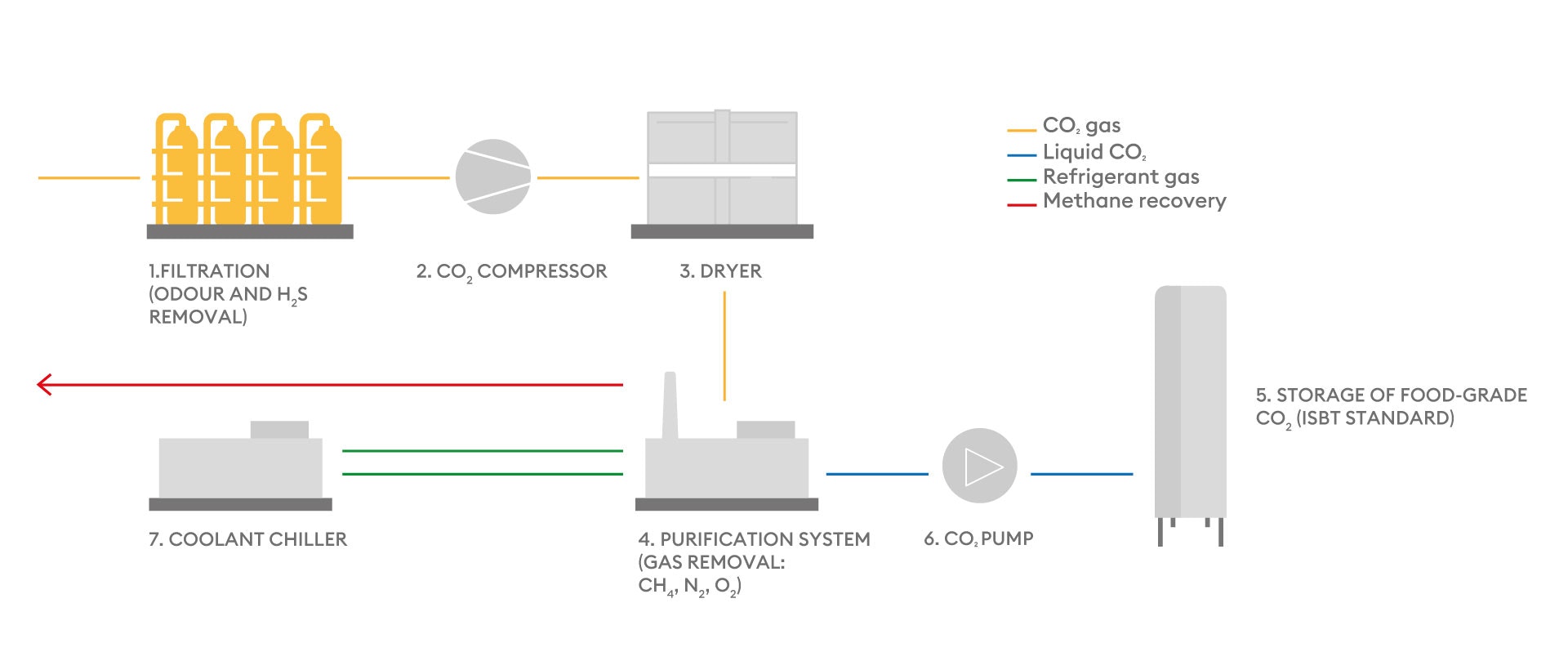

The plant is based on an integrated cryogenic process divided into 5 phases:

Treatment: during the first part of the process the purification system eliminates contaminants and odours through a system of activated carbon filters.

Compression: the gas is compressed to a pressure between 15 and 20 bar according to the customer's needs.

Drying: moisture is reduced through condensation and absorption on molecular sieves.

Cryogenic distillation: the extraneous gases (CH₄, N₂, O₂) present in the incoming mixture are separated from carbon dioxide by means of cryogenic distillation technology, which enables obtaining CO₂ with a content greater than 99.9% at the exit of the system, as required by the ISBT.

Storage: The bio-CO₂ is conveyed into a storage tank where it will be kept at the desired pressure and temperature conditions.

DISCO₂VERY

Strengths

Industry

Brochure

Corporate

One Stop Shop