CH4LNG

- Home

- CH4LNG

The solution for the liquefaction of biomethane

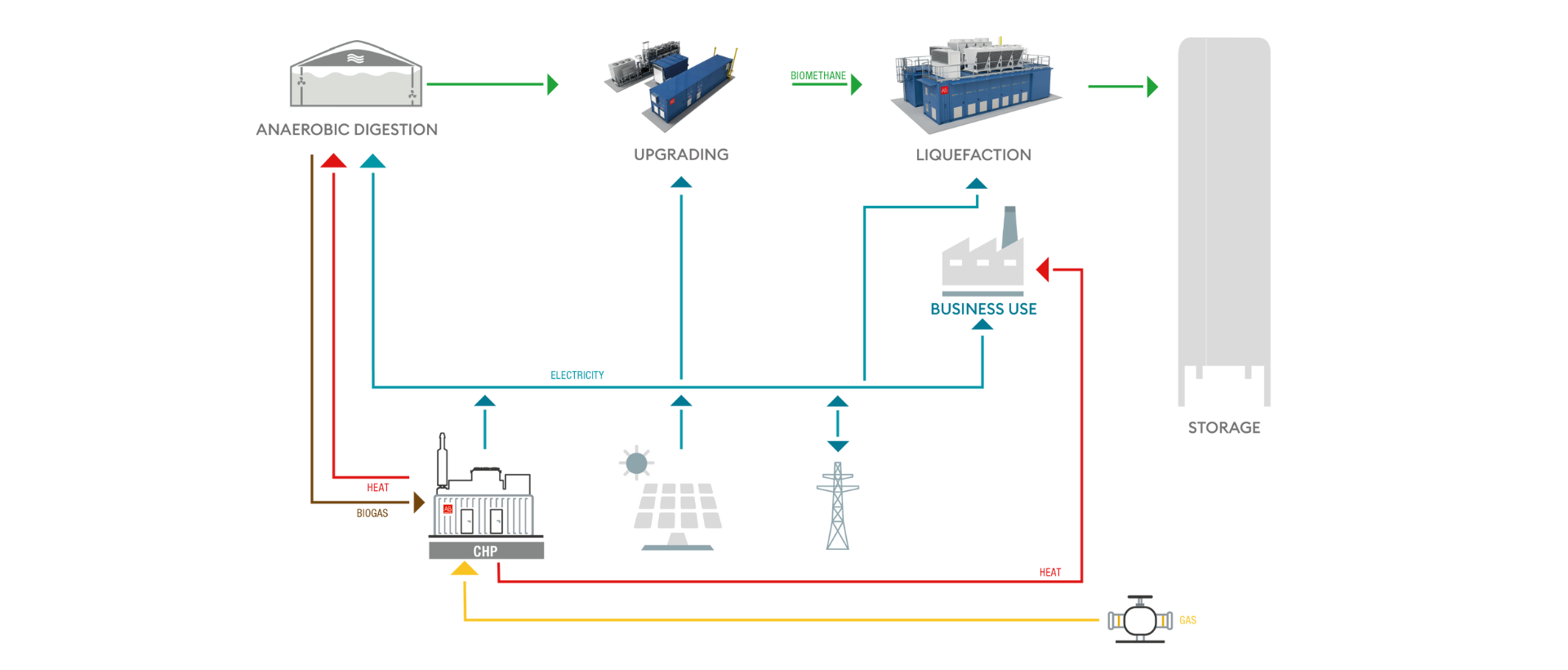

If the injection of the biomethane produced into the grid is not possible, the biomethane can be liquefied for transport by road. To this end, AB has created CH4LNG, the solution for the liquefaction of biomethane designed to be installed downstream of a BIOCH4NGE® system, with which it integrates perfectly.

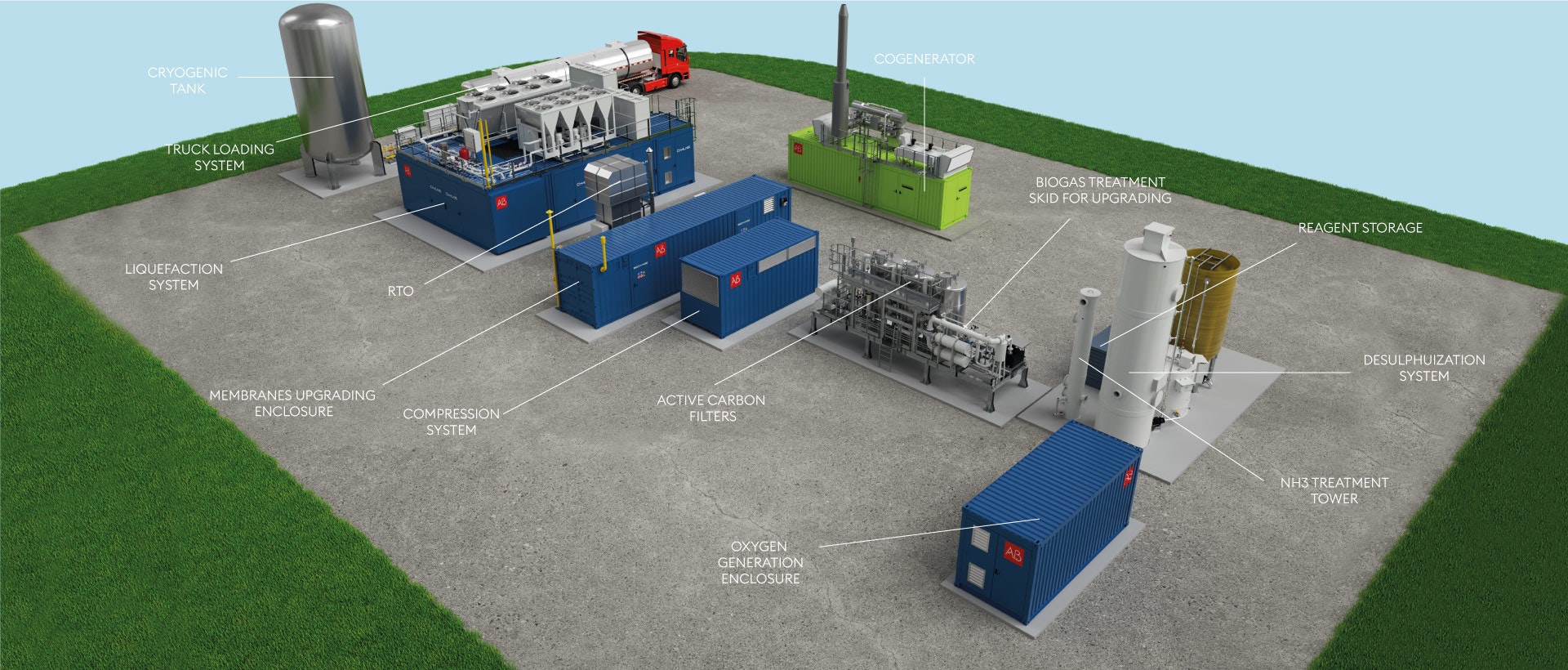

Render 3D

*example image Layout and elements to be defined based on the available spaces and the configuration chosen

Integrated cryogenic process

It is based on an integrated cryogenic process, at low operating pressure, divided into 3 phases: treatment, liquefaction and storage.

Treatment: In the first part of the process, the TSA (Temperature Swing Adsorption) purification system lowers the moisture and CO₂ content through molecular filters and sieves.

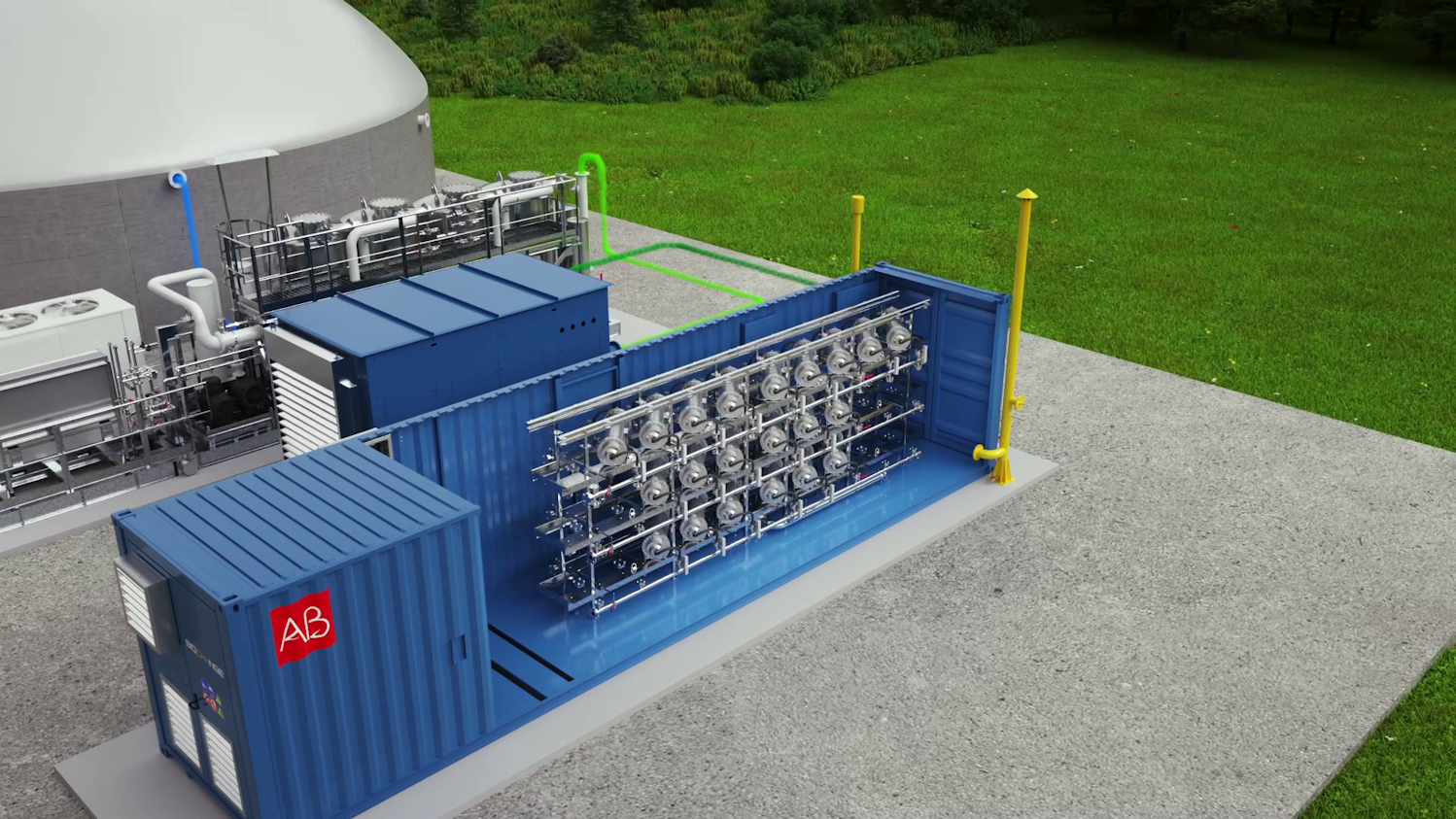

Liquefaction: through several cooling stages, the biomethane under pressure passes to the liquid state and is made available at conditions of <-145° C and 3 bar. The heart of the CH4LNG process is the cryo-cooler, based on Stirling Cryogenics technology, which is an alternative machine that generates cooling power by compressing and expanding helium in a closed cycle.

Storage: the bio-LNG is conveyed to a transfer tank, where the desired pressure and temperature conditions of the final product are achieved.

Available for small plants

The cryogenic process behind the CH4LNG system uses only electricity, for example, avoiding the use of liquid nitrogen. CH4LNG is a highly efficient containerized modular solution, which works without the use of liquefied technical gases, also available for small plants.

The advantages of CH4LNG

Modular and compact

Simple and very efficient process

No liquid nitrogen required

Granularity up to 1 TPD (1 cryogenerator)

Constant specific consumption