Biogas-to-biomethane upgrading

- Home

- Biogas-to-biomethane upgrading

What is biomethane?

Biomethane is a renewable gas obtained by putting raw biogas through a purification process called upgrading. Raw biogas can be obtained from anaerobic digestion of various raw materials: agricultural biomass (by-products, agricultural waste and animal waste), agro-industrial waste (waste from the processing of the food chain) or the organic fraction of municipal solid waste (OFMSW).

Once the biogas-to-biomethane upgrading has been carried out, it must be refined, in order to eliminate the components that are not suitable for feeding the gas into the network (CO₂).

Products

How does the biogas-to-biomethane upgrading process work?

Biogas-to-biomethane upgrading is a complex treatment whose end result is the removal of CO₂ from raw biogas. The process consists of several phases: a first pre-treatment step, followed by a purification phase, i.e. of removal of pollutants (H₂S, VOCₛ) from biogas coming from the anaerobic digester and a final phase of methane separation (CH₄) from carbon dioxide.

The end result is a renewable energy source, biomethane, which reduces emissions, exploiting existing networks and increasing national production, with positive repercussions in terms of circularity in the use of resources in the agri-food sector.

Biogas-to-biomethane upgrading with selective membrane technology

Different biogas-to-biomethane upgrading technologies are available on the market, which are based on different chemical-physical principles related to gas separation.

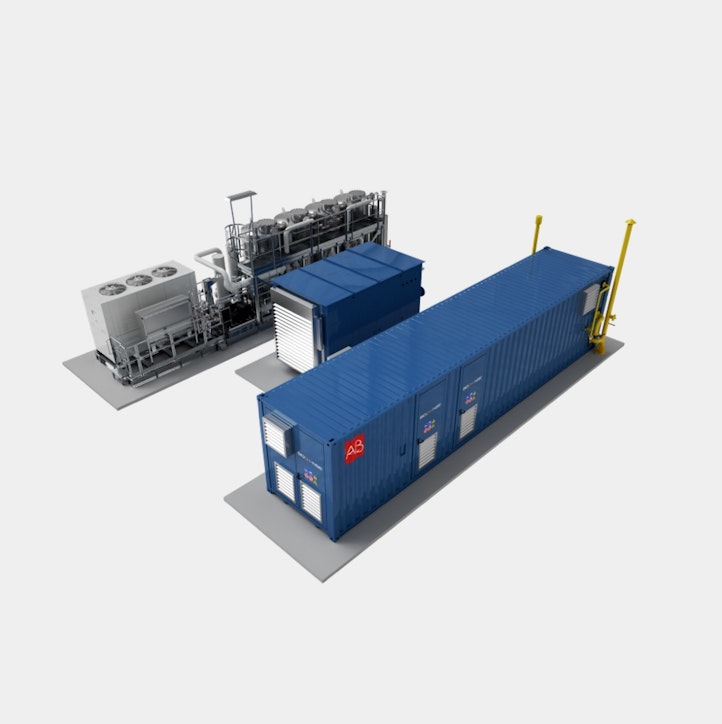

Among the most widespread and effective there is the biogas-to-biomethane upgrading using selective membranes, also chosen by AB for BIOCH4NGE®: the use of particular polymeric materials that have a selective permeability to separate CH₄ and CO₂ and that guarantee perfect purification from carbon dioxide, thus reducing biogas loss during upgrading to almost zero.